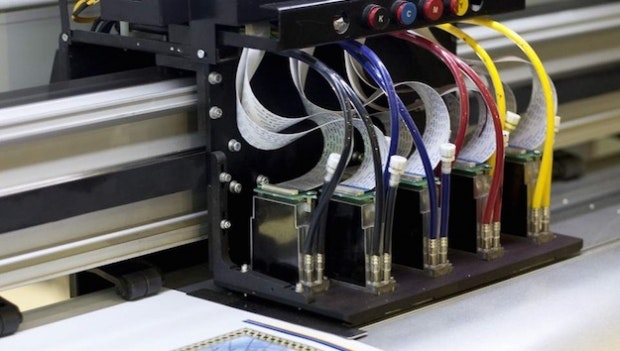

Founded in 2012, APS Engineering creates cutting-edge ink delivery systems for industrial inkjet printing, as well as print bar design and consulting services for custom projects. Jaren Marler, APS Engineering’s founder, previously spent 23 years at HP as a product developer and played a pivotal role in defining inkjet technology in the early 2000s. Seeking to bring greater flexibility and savings to his clients, Jaren wanted to provide an alternative to the predominant proprietary inkjet systems in industrial applications.

His initial focus was on ink pump controllers, as there was a complete lack of cost-effective, smart, and adaptable options for his clients. While doing the research for initial prototypes, Jaren found that nearly all Programmable Logic Controllers (PLCs) on the market cost thousands of dollars, and the alternative of designing a custom chip-down PCB board wouldn’t be any better. Instead, he looked to Arduino for a solution.

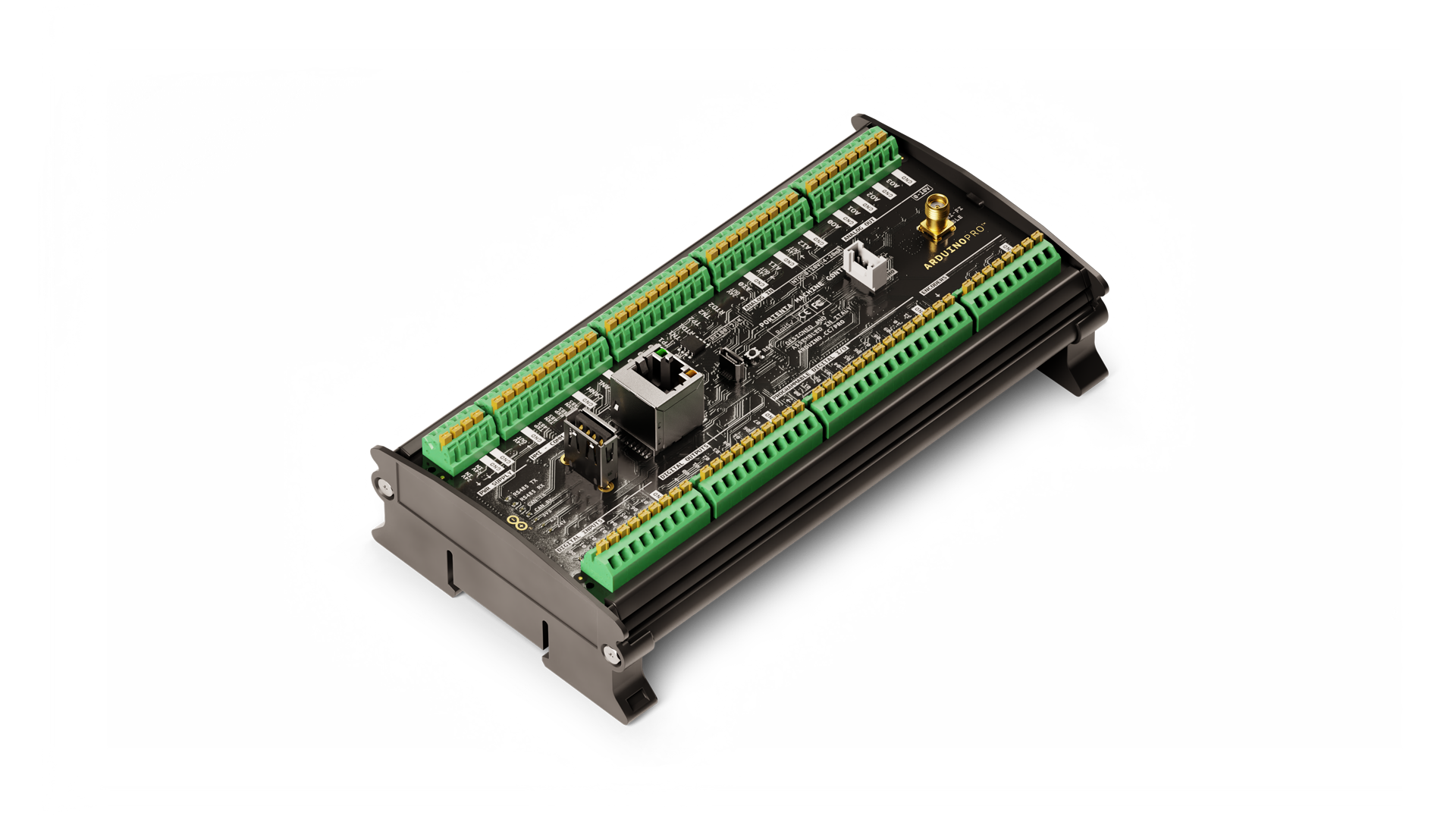

“Frankly, I wouldn’t be in business today if I were still using other industrial PLCs. In the end, Portenta Machine Control saved me over $2,700 for each unit. I now have a system that does everything I want.”

Jaren Marler, President of APS Engineering

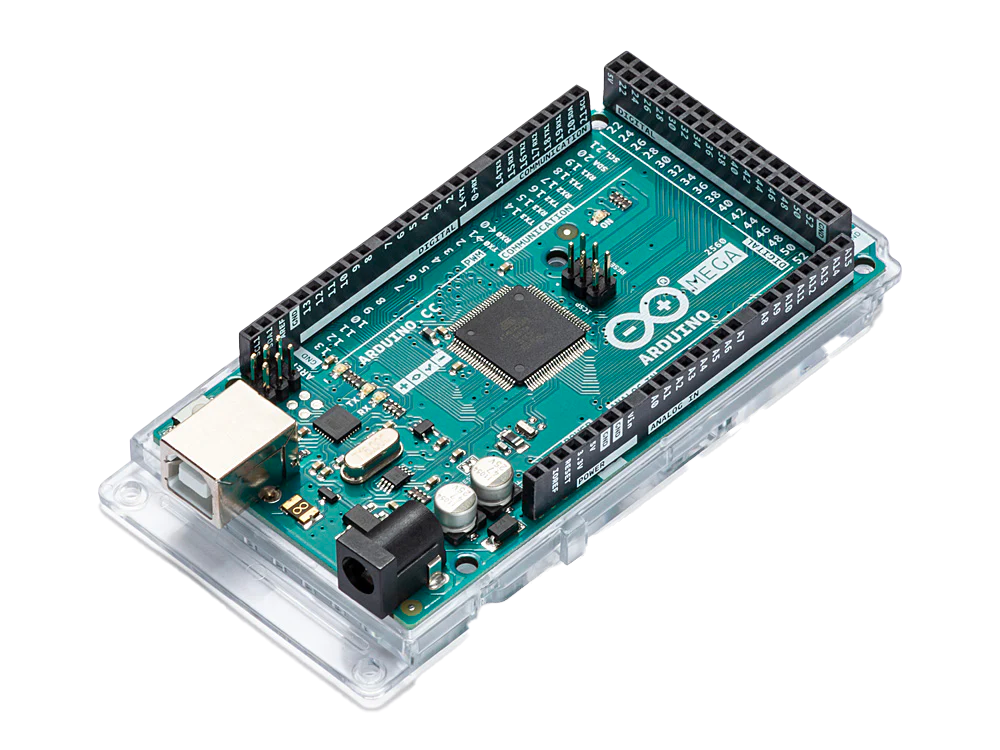

Jaren used an Arduino Mega 2560 Rev3 to create the first prototype. This was a major advancement in ink pump controller capabilities, even surpassing his competitors, who offered fewer functions at a higher cost. Arduino’s open platform unlocked the ability to integrate with other systems and control multiple processes simultaneously. Through the prototyping process, Jaren saw that Arduino’s build quality, board features, and toolchain would also be suitable beyond a proof-of-concept and were the best option for production quality applications.

With a successful prototype on the Mega 2560 Rev3, Jaren required more features for production units. The Arduino Pro Portenta Machine Control proved to be ideal for his needs, providing a certified, cost-effective, and customizable platform to manage the new ink pumping systems.

Comparable PLC units cost almost 10x as much as Portenta Machine Control, so even including R&D and custom development Jared is able to profitably offer his clients a top-of-the-line solution at half the price he would have had to charge using any other option.

Compatibility with a variety of I/O options, analog and digital, sensors and actuators, PWMs, I2C communication, and Ethernet and serial interfaces enabled a wide range of functionalities to be consolidated into one compact solution. Through Portenta Machine Control’s Ethernet and serial communication, APS enabled multiple paths for end-users to interact with the controller using intuitive graphical user interfaces (GUIs) for real-time feedback and remote control of the unit.

By remaining within the Arduino ecosystem throughout development, the software transferred from prototype to production quickly and seamlessly. Overall, saving on engineering services and accelerating time-to-market by months.

APS’s ink pumping systems have found applications across diverse industries, catering to a myriad of needs for customers ranging from in-house manufacturers to OEM suppliers. Be it printing on water bottles, cardboard packaging, 3D sand casting, ceramics, textiles, or even cars and commercial airplanes, their Arduino-based system has provided reliable, efficient, and affordable solutions to empower businesses and individuals to explore new possibilities in their respective domains.

Unrelenting in his pursuit to bring further innovation to his clients,, Jaren now plans to include Arduino Pro Opta PLC in future pumping systems. This will power additional capabilities for his customers and enable his business to access an even wider range of clients. With a strong focus on research and development, APS Engineering aims to continuously enhance its offerings, cater to evolving client needs, and provide innovative solutions to customers worldwide.