Rinaldi Superforni is a historical company with a vision for the future, powered by the opportunities technology offers.

Founded in 1946, it stands out today as one of Italy’s major manufacturers of professional ovens for pizza restaurants, pastry shops and bakeries. Led by the founder’s three grandsons, the company is constantly looking for new ways to strengthen its products’ positioning as the most technologically advanced and high-performance solutions for the increasingly demanding user.

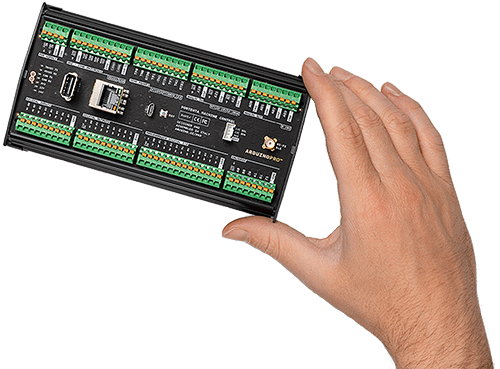

Production-oriented and bold, they decided to partner with Arduino to develop a solution they could integrate into their ovens to make them truly “intelligent” and to provide clients with an improved experience. After some months of work side-by-side, we had perfected the Portenta Machine Control and enabled them to land on a new and exciting business paradigm.

“The introduction of the Portenta Machine Control will revolutionize the way in which we sell our products. Some of our new models will be sold not as simple and static machines, but as a dynamic service.”

MATTEO NISCOSI, HEAD OF R&D AT RINALDI SUPERFORNI

Rinaldi Superforni integrated the Arduino PMC into its ovens to provide a better user experience and better customer service, with top versatility and independence.

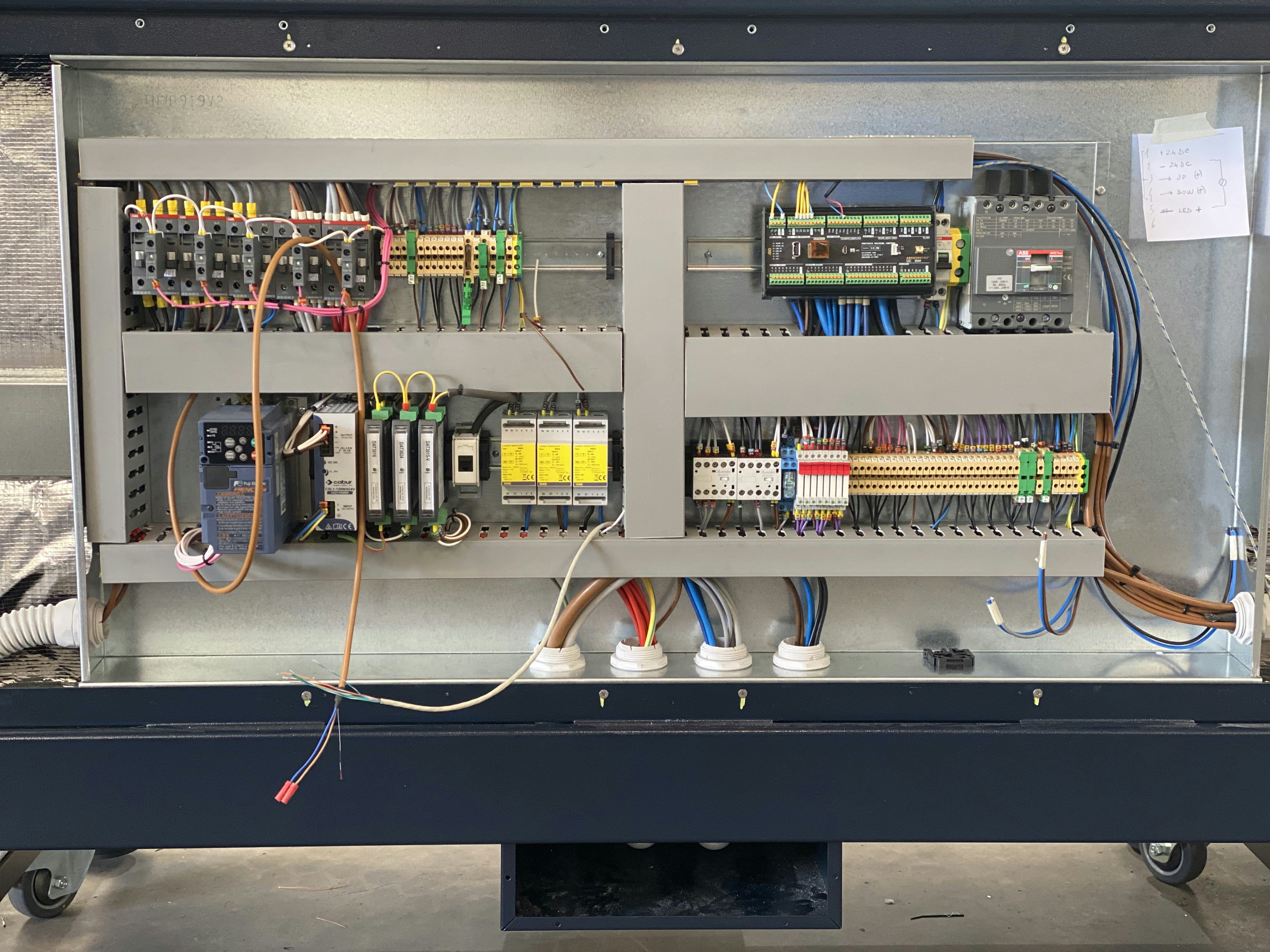

Integrating the PMC into professional appliances means Rinaldi Superforni now can:

- Allow customers to connect to products remotely: bakers can start pre-heating the oven on their way to work, or be alerted if the sourdough machine stops working over the weekend due to a blackout.

- Offer excellent maintenance service: a worn component can be automatically detected, triggering a preventive maintenance suggestion; the technical assistance department can check the product remotely and provide feedback or even carry out maintenance on the software remotely.

- Gather data to constantly improve: a connected device offers infinite opportunities to find out more about habits, usage, preferences and more – all precious information for the development of new models and innovations that make customers’ life better.

- Change business model completely: usage-based rental contracts are possible and straightforward, thanks to products’ ability to store and transmit data.

“Thanks to the software infrastructure built by Arduino, we are now able to control and monitor thousands of ovens at the same time, all around the globe.”

MATTEO NISCOSI, HEAD OF R&D AT RINALDI SUPERFORNI

Why the Portenta Machine Control?

Like most manufacturers, the company makes a variety of different oven models – from industrial tunnel ovens to smaller professional appliances destined to restaurants. The PMC can be used across the gamut, simply by programming it in different ways. Versatility means having one hardware, one supplier, for all the products in your catalog.

Furthermore, by testing and developing their solution with Arduino, Rinaldi Superforni acquired the know-how – and the freedom – to program and manage their products. They will never have switching costs if they decide to change: the PMC gives them the freedom and independence they need.

We couldn’t do it without you: customization is central to the Arduino approach.

We are famous for our open-source philosophy. But not everyone stops to think of the many benefits this brings to our users:

- No vendor lock-in: you can program your Arduino solution and customize it to your needs, adapt it to any change, scale it up – and even recreate it completely independently if you wish.

- Shorter learning curve: our products and solutions are easy to use and intuitive even for engineers with limited programming background. This means you can train people on your team – or even a single person – and integrate the skills you need to manage and control the hardware and software that go into your products.

- Complete customization: you can access, upgrade and change anything you want. In fact, we’ll help you do it. We even have a specific program that fast-tracks your innovation capabilities using our solutions. Do you want to become a true innovator in your industry? Find out more about the Arduino Systems Integrator Program.