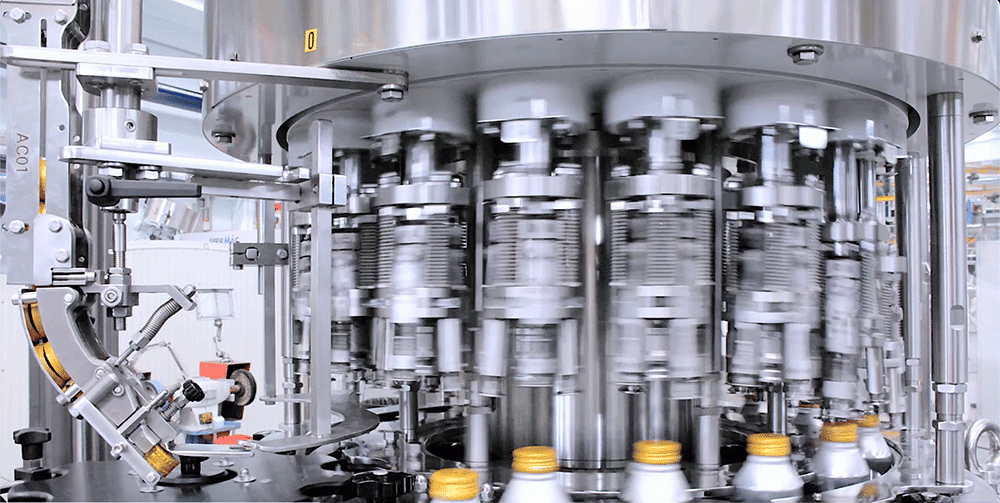

Advanced capping lines must provide great speed and precision. Why not enable these crucial success factors with a smart solution?

Based in Canelli, Italy, AROL is a leading provider of innovative and custom capping and closure system machines, with over 25,000 pieces of equipment currently installed around the world. Their capping machines output up to 100,000 bottles per hour – enough to fill over 10 trucks: and while this huge yield is a great selling point, it also means any minute of downtime can cost their clients.

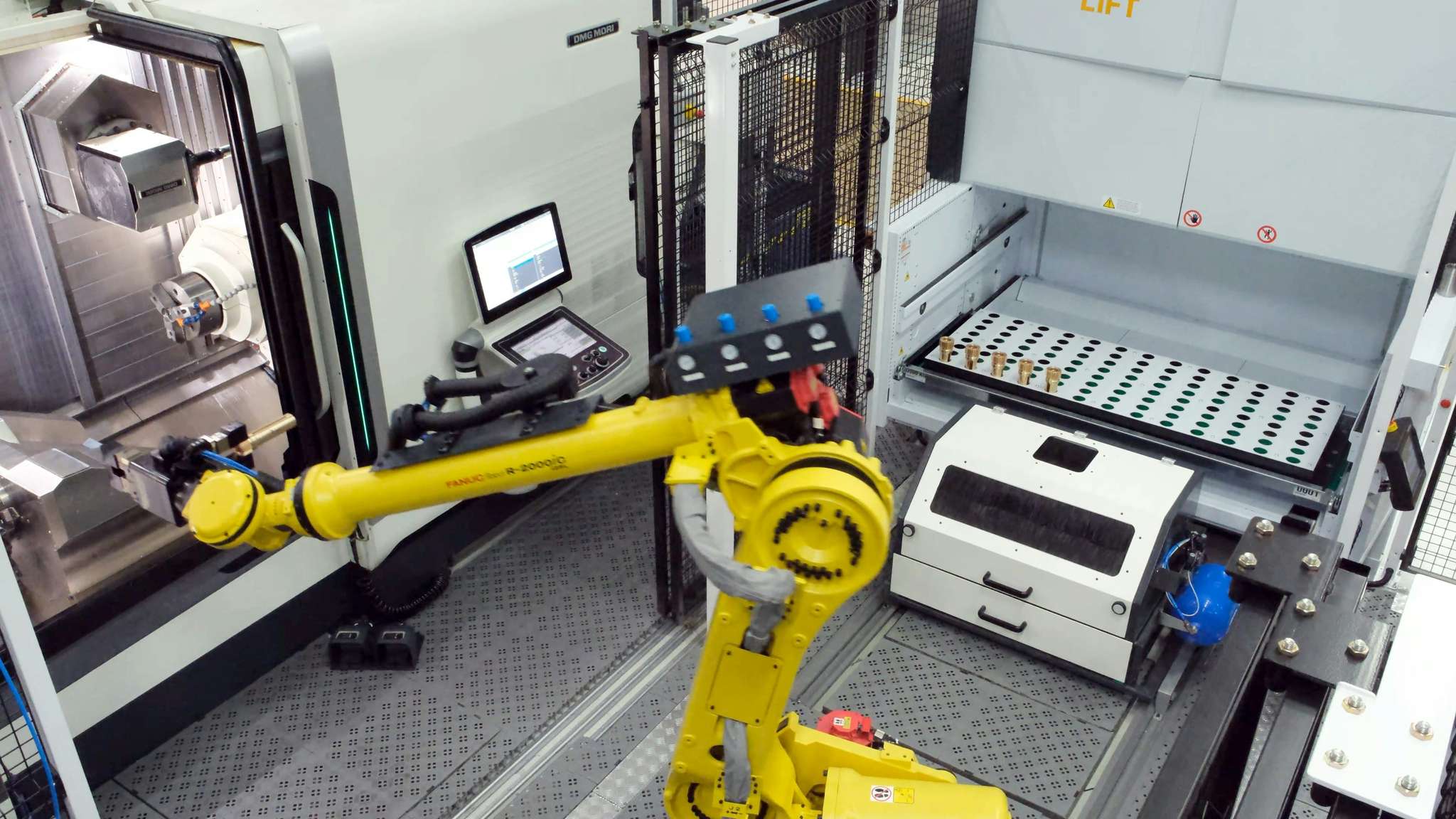

To support diagnostic, prognostic and predictive maintenance, they decided to draw on their experience to develop a smart solution able to gather data from industrial equipment and the surrounding environment, creating a machine monitoring system based on remote wireless sensors that could be powered by battery or 24 V.

The project faced specific challenges in the fact sensor nodes had to be mounted in rotating capping turrets, fitting in a small space and yet always remaining connected to a communication unit at the base of the line. What’s more, they had to perform part of the data processing on the edge, in order to not overload the central system. And of course, the upgraded capping machine had to be made smart without costing sensibly more.

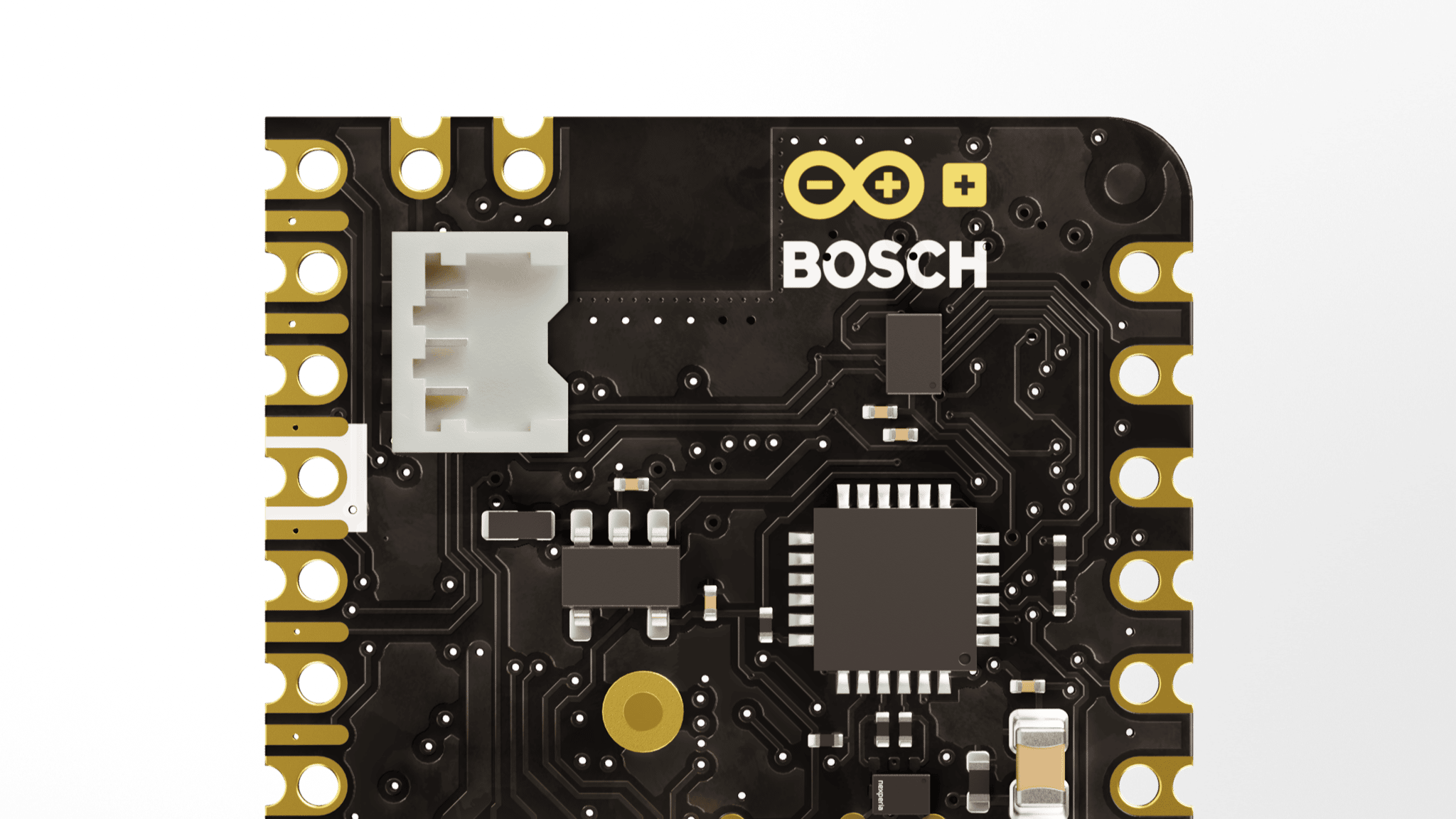

Combining 15 Arduino Pro Nicla Sense ME modules with one Portenta Machine Control allowed AROL to quickly develop and test a working solution.

Each capping turret was fitted with a compact Nicla Sense ME, providing vibration and temperature detection thanks to state-of-the-art, onboard sensors – as well as the computational power to process data on the edge. Data coming from the capping turrets are then sent via Bluetooth® to a Portenta Machine Control, mounted on a DIN rail at the base of the industrial equipment.

“Arduino Pro products are designed to address our industrial-level requirements. Arduino engineers proactively supported us in understanding our requirements and providing a business-oriented solution with a customer-focus approach.”

Denis Ruffino, R&D technical director at AROL

Ease of use and flexibility mean faster time to market.

The Arduino ecosystem is perfect to prototype, test, and develop new solutions with little time and zero hassle. But that’s not all there is to it. The Arduino Pro range takes our open, modular and cost-effective approach from the lab to the factory, allowing your R&D team to scale up their ideas with limited refactoring.

Not convinced? Check out the outstanding computational density on our Portenta X8, the IoT capabilities of our Opta micro PLC, or the number of tech features packed on the boards in the compact Nano family. Each and every component we provide comes with extensive documentation, tutorials, project ideas, and outstanding support. Because our goal is to help you become the innovator of your industry.